years of stability

Since 1992, Umut Construction, aiming for excellence in the construction sector, has become one of Turkey's reliable building manufacturers with more than thirty years of experience. With an annual average of 200.000 m² closed area project design and contracting capacity, we offer a wide range of services from industrial facilities to luxury residences.

We specialise in factories, industrial sites, educational institutions, mass housing projects, shopping malls, public buildings, private villas, landscaping and infrastructure works.

We bring together quality, durability and aesthetics in every project.

As Umut Construction, we have adopted the principle of producing environmentally sensitive and sustainable solutions while making our customers' dreams come true.

While building the structures of the future, we protect the values of today.

Since the day it was founded, Umut İnşaat has adopted the principle of constructing reliable, high-quality, and sustainable structures. In its early years in the construction sector, our company began with small-scale projects and quickly gained momentum thanks to the trust it built, its meticulous workmanship, and a strong focus on customer satisfaction.

In its early years, Umut İnşaat made its mark in the sector with successful project completions and gradually expanded its expertise over time. Today, we proudly carry out a wide range of projects including factories, industrial complexes, educational facilities, mass housing projects, shopping malls, public buildings, residential villas, as well as infrastructure and landscaping works.

By closely following technological developments, our company has embraced digital transformation in design, engineering, and implementation processes. We continuously improve our quality and occupational health and safety standards in line with modern expectations.

In recent years, Umut İnşaat has also taken an active role in the renewable energy sector, leading environmentally friendly and sustainable initiatives—particularly through its work on Wind Power Plant (WPP) projects.

Today, with an average annual project capacity of 200,000 m² in closed construction area, Umut İnşaat continues to build not only physical structures, but also trust, quality, and long-term value.

Empowered by its past and looking to the future with hope, our company continues to add value to our country through its engineering expertise, experienced team, and strong business partnerships

Founded in 1982, Umut İnşaat took its first steps in the construction industry with modest projects and quickly made a name for itself in the sector with its emphasis on quality, trust, and sustainability. From the day it began operations, our company has prioritized precision in construction, engineering discipline, and customer satisfaction, laying the foundation for its current corporate identity during this period.

In line with the growing business volume, increasing project diversity, and the need for corporate restructuring, Umut İnşaat became a joint-stock company in 1992. This transformation strengthened our corporate vision and paved the way for us to play a more effective role in large-scale projects. As Umut Construction Inc., we continue to strengthen our legal infrastructure and organizational structure to reinforce our leading position in the industry.

The Bursa Fruit, Vegetable, and Fish Market construction project has been one of our important projects contributing to modern urban infrastructure. The meticulousness and quality-oriented approach we demonstrated in the planning, implementation, and delivery processes of the project have been appreciated by industry authorities.

As a result of this successful work, our project was deemed worthy of an award, once again confirming Umut İnşaat's engineering capabilities and success in project management.

This facility, which continues to serve Bursa's commercial life today with its modern infrastructure, is one of the examples that demonstrate our company's competence and reliability in public projects.

As Umut İnşaat, we participated in the construction of Kent Meydanı Shopping and Lifestyle Center, one of Bursa's most prestigious projects in 2007, playing a role in the realization of an important structure that will contribute to the commercial and social life of the city.

As Umut İnşaat, we participated in the Bilecik Cement Factory project, which has made a significant contribution to our country's industrial infrastructure, both as a construction contractor and as an investment partner.

This project has been a strategic step that has demonstrated not only our company's technical strength in the field of construction but also its identity as an investor. By incorporating our engineering expertise and project management experience into this facility, we ensured that the factory was completed on time and to high-quality standards.

This facility, which is still actively producing today, serves as a testament to Umut Construction's expertise in industrial structures and its long-term vision.

As Umut İnşaat, we have begun to establish our presence in the energy sector by participating as an investment partner in our first Wind Energy Plant (WEP) project. With this project, we have gained experience in the field of renewable energy and have taken concrete steps to realize our commitment to environmentally conscious and sustainable investments.

Our company, which aims to contribute to the future of our country not only in the construction sector but also through energy investments, continues to support sustainable development with projects that are respectful of nature, efficient, and long-lasting.

The 75-bed Geo Hospital we built in Georgia is Umut İnşaat's first turnkey project abroad. With the successful completion of this healthcare facility, which meets modern hospital standards, we have concretized our goal of operating in the international market and expanded abroad.

This project not only demonstrates our technical capabilities but also our ability to manage projects effectively and collaborate across different regions. The successful completion of this hospital in Georgia marks the first milestone in Umut Construction's vision for global growth.

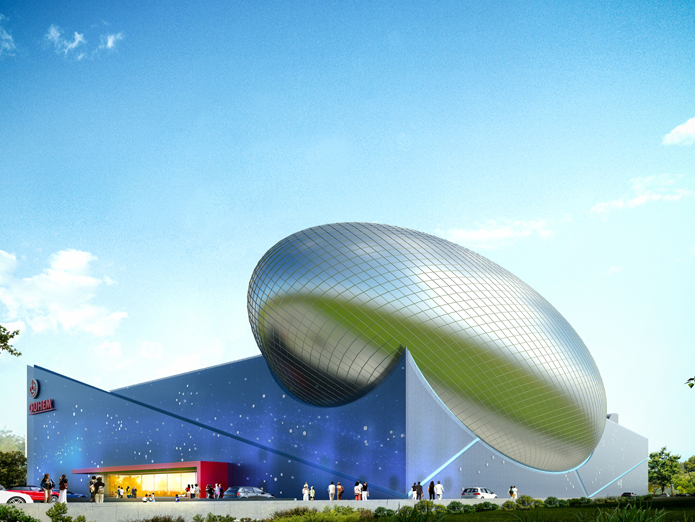

Our company has successfully completed the construction work we undertook for the Gökmen Space Aviation Education Center (GUHEM) project in Bursa, thereby contributing to one of our country's most important investments in science, technology, and education.

This project, one of Turkey's first and most comprehensive centers focused on space and aviation, stands out for its architectural aesthetics, technical infrastructure, and high engineering standards. As Umut Construction, we ensured the center was completed on schedule by rigorously applying quality, time management, and workplace safety principles throughout the construction process.

Our affiliate Alibeyres Rüzgar Enerji Üretim A.Ş. was established on November 25, 2002. In accordance with the approval obtained from the Energy Market Regulatory Authority (EPDK), the construction of 9 turbines (30 MWe), a switchyard, and a control building was completed, and electricity production commenced. Subsequently, through the construction of three additional turbines (11.8 MWe), the capacity was increased, bringing the total installed capacity to 12 turbines and 41.8 MWe.

We successfully completed the turnkey Press Building project constructed in Gölcük for Ford Otosan, Turkey's leading automotive company. With this project, we once again demonstrated our engineering strength and project management capabilities.

We were involved in the Battery Building project for Ford Otosan, utilizing modern engineering solutions and high-quality construction techniques. The project stands out for its advanced technology-compatible design and sustainable construction approach.

The strong network of references we have built over the years through the trust we have earned and our achievements is one of the most important indicators of our position in the industry. As Umut Construction, we have built a broad customer portfolio through the quality approach we demonstrate in every project and our customer satisfaction-oriented approach.

Our reference network is strengthened not only by the projects we have completed but also by our long-term business relationships. Our customers' repeat requests and recommendations are a testament to the fact that our quality standards are recognized and appreciated by the industry.

Total Construction Area: 28,000.00 m²

Bilecik Cement Factory 3.300 Tons / Day Integrated Cement Product Facility

Total Construction Area: 41.000 m²

Total Construction Area 60,000 m²

5+5 Total Installed Capacity of 10 MW

Bursa Metropolitan Municipality City Market Construction. Fruit and Vegetable Market; 52,500 m² Construction Area, 2,000 Ton Steel Works. Fish Market; 6,000 m² Construction Area, 500 Ton Steel Works, administration building:2.500m²

Buseb Inc. in Bursa Free Zone; administrative building, Free Zone Directorate and Customs Directorate administrative buildings, 15 infrastructure transformer buildings, 10,000 m² space roof, steel structure warehouse building, two 5,000 m² space roofs, a steel-framed warehouse building, retaining structures, 30 shops each measuring 300 m², and a customs entrance structure.

Total Construction Area 12,800 m²

Installation of 30 Turbines, Construction of Switchyard and Control Building, Construction of Access Roads

Total Installed Capacity: 77.4MW

Total Construction Area 7,380 m²

Total Construction Area 50,400 m²

8 Turbine Platform and Foundation, Transportation Routes and Culverts Construction Work

Total Installed Capacity: 56MW

Total Construction Area: 27,528 m²

Installation of 25 Turbines, Construction of Switchyard and Control Building, Construction of Access Roads

Total Installed Capacity: 104MW

Ground Improvement Details:Jet Grouting: A total of 46,650 linear meters of jet grouting was executed to improve soil conditions. This technique involves injecting a cementitious grout at high pressure to enhance the soil's bearing capacity and reduce the risk of liquefaction and settlement. Bored Pile System: A deep foundation solution was implemented with 8,260 linear meters of bored piles to bypass weak soil layers and provide high load-bearing capacity. Diaphragm Wall: A 4,900 m² diaphragm wall system was constructed for excavation support, slope stabilization, and groundwater control.

Structural Systems: Steel Structure: The main structural system is a steel frame, totaling 3,200 tons. This includes steel columns and a roof structure designed for large clear spans and high loads. Underground Infrastructure: This includes specialized underground systems for press lines, conveyor systems, and machine foundations. Reinforced Concrete Foundations: The facility is founded on reinforced concrete foundations, designed to distribute industrial loads evenly.

Mechanical, Electrical, and Automation Systems: Crane Systems: The facility is equipped with two overhead traveling crane systems: one with a capacity of 60 tons and another with a capacity of 30 tons. Electrical Infrastructure: The power supply is managed by a 2500 kVA transformer, supported by a robust electrical infrastructure including MV/LV switchgear and distribution panels. Automation: A comprehensive automation system was installed, including SCADA and PLC controls, with full integration into the existing factory's systems.

MEP Systems: The project includes complete fire suppression, HVAC (Heating, Ventilation, and Air Conditioning), and fire detection systems. Specialized Areas: Test Rooms: Dedicated areas were constructed for specialized operations, including a teardown and disassembly test room and a tensile test laboratory. These rooms feature reinforced floors, sound insulation, and specialized ventilation. Utility Systems: A 750 m³ underground greywater tank was built for water management. The facility also features well-equipped WC blocks and locker rooms.

Industrial Doors: The building is fitted with a variety of industrial doors, including logistics doors for loading and unloading, and fire-rated emergency exit doors with panic bar systems. Finishing and Site Infrastructure: Cladding: The roof is covered with a composite panel cladding system for thermal insulation and weather protection, while the facade features a cassette panel cladding system for a modern aesthetic and energy efficiency.

Site Development: The surrounding area includes extensive landscaping, paved roads, and logistics infrastructure to support efficient operations.

Total Construction Area: 16,800 m².

1.210 Tons Of Steelwork

Total Construction Area: 9.400 m²

Total Construction Area 34,000 m²

Total Construction Area 50,000 m²

Total Construction Area 90,000 m²

Total Construction Area: 13,650 m²

Total Construction Area 32,000 m²

Total Construction Area: 49,500 m²

Total Construction Area: 9,000 m²

Total Construction Area: 12,000 m²

Total Construction Area 27,528 m²

Total Construction Area 17,300 m²

Total Construction Area 75,000 m²

Installation of 21 Turbines, Construction of Switchyard and Control Building, Construction of Access Roads

15,285 meters of Ø40 and 880 meters of Ø100 bored piles,

525,000 m³ of excavation and 400,000 tons of backfill,

10,000 m³ of concrete and 2,000 tons of construction steel

Total Installed Capacity: 100MW

1 Subway Station

1 Surface Station

Greenhouse A, Packaging and Service Building, Buffer Tank Construction. Greenhouse B Ground Lime Stabilization and Perimeter Retaining Walls Construction.

Total Construction Area 37,000m² Greenhouse A.

Total Construction Area 4,300m² Offices, Service and Packaging Building.

Total Construction Area 620m² 2 Buffer Tanks

Total Construction Area 42,000m² Greenhouse B Excavation and Ground Lime Stabilization

Approximately 2,000 meters of retaining walls at varying heights

Total 1,200 m³ gabion wall

Total 3,000 meters of Ø80 Fore Piles

Construction of 2 Turbine Platforms, Foundations, Access Roads, and Culverts

Total Installed Capacity: 6.8MW

With people and projects in more than 33 countries, our reach and expertise are unmatched. At Umut Construction, we don’t just take on the world’s most challenging projects — we solve them. Whether safely dismantling radioactive materials, tunneling through densely populated cities, strengthening critical supply chains, or safeguarding infrastructure, we lead with innovation and collaboration.

From engineers and project managers to skilled craft professionals, we seek colleagues with diverse and global perspectives who are ready to embrace challenges and push the boundaries of what’s possible.